Tirupur being the hub of knitwear has more than 30 thousand textile based industries (knitting units, dyeing & bleaching, fabric printing, garment making, embroidery, finishing and other ancillary units) including small, medium, large structures provides employment to more than six lakh people being the only medium of their earning.

Tirupur like any other industrial town faces it’s share of environmental pollution complaints.

Dyeing and printing units took the responsibility and the collective effort brought a positive result when in 2012 Tirupur became the first textile cluster in India to achieve Zero Liquid Discharge in their textile based units.

We support such efforts and we work with the facilities who are aware of their accountability and responsibility in the eco-system.

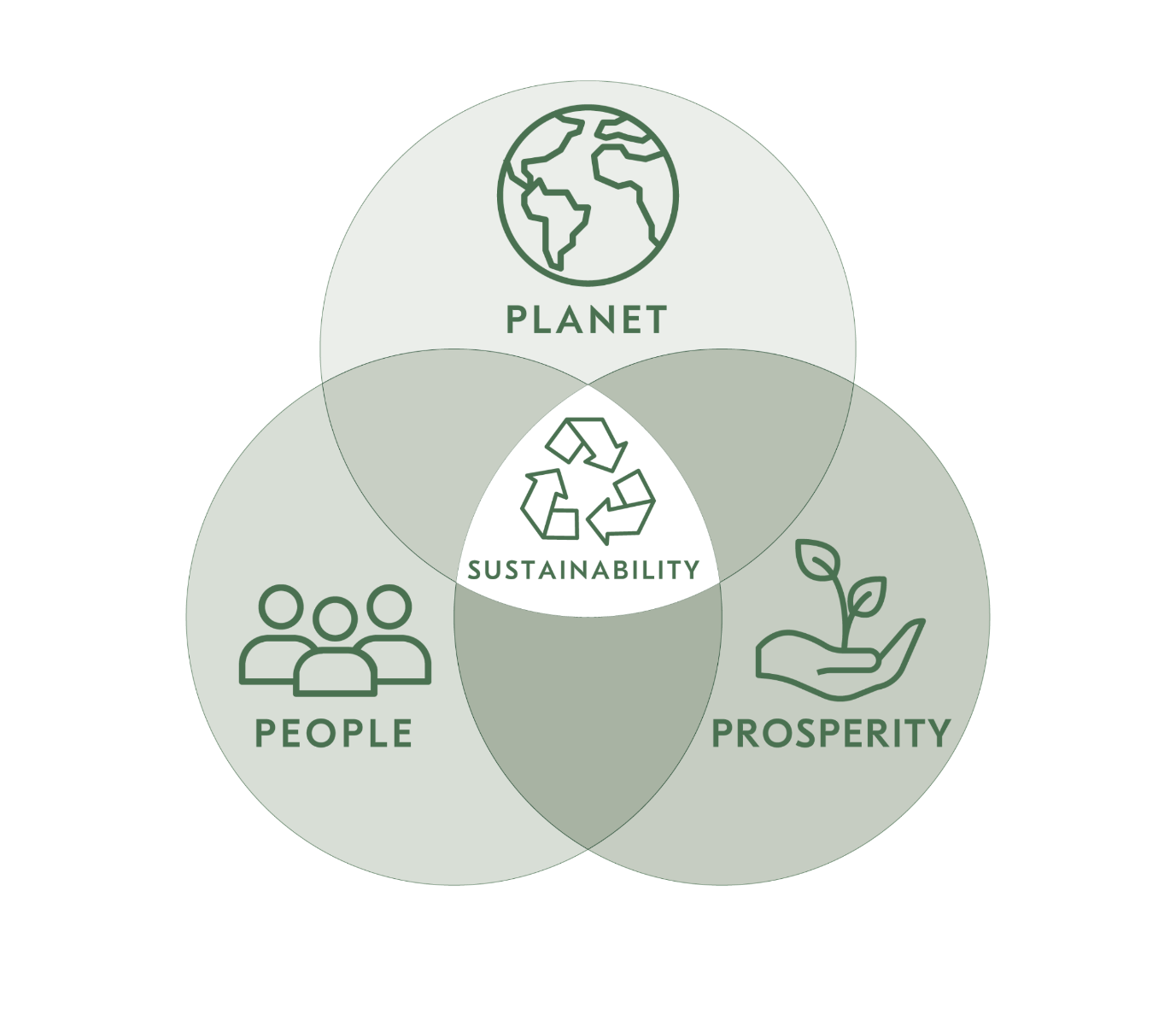

Sustainability lies in what we get from nature and what we giving back. We encourage optimum use of resources and promote sustainable fashion by encouraging organic fabric, recycled yarn, plastic free packaging, Organic dyes (has limitations chemical dyes being used under chemical regulations set by the government), printing and bio finishes.

We are working in factories who are compliant to guidelines and care for the teams and the creator of the product. Amidst the global pandemic Covid -19 our priority is more towards labour safety and health, to make sure that facilities ae following the guidelines issued the by the government.

Workman health and safety measures.

– PPE kits to workman – masks, gloves, specs, earplugs, hand sanitizer.

– Worker welfare measures like safety and harassment committee, EPF and ESI, standard working time of 8 hours 6 days a week, leaves, holidays, on-time salary.

– accessibility to basic amenities like – drinking water, toilets, first-aid, adequate ventilation, proper lightening, cleanliness and hygiene at woke place, regular maintenance and check-up of machinery.

– Machine operation training to reduce work place hazards.